When it comes to UV DTF (Direct to Film) sticker printing, there are two main options to consider: the UV DTF flatbed printer machine and the UV DTF roll-to-roll machine. Both have their own unique features and advantages, making it important to understand the differences in order to make an informed decision.

The A2 A3 UV DTF flatbed printing machine offers the ability to print directly on items, making it a versatile option for printing on various surfaces. It is also capable of printing on UV DTF film and then transferring it to items, making it suitable for small batch production. This method may be slower, but it is multi-functional and suitable for printing different items across various industries.

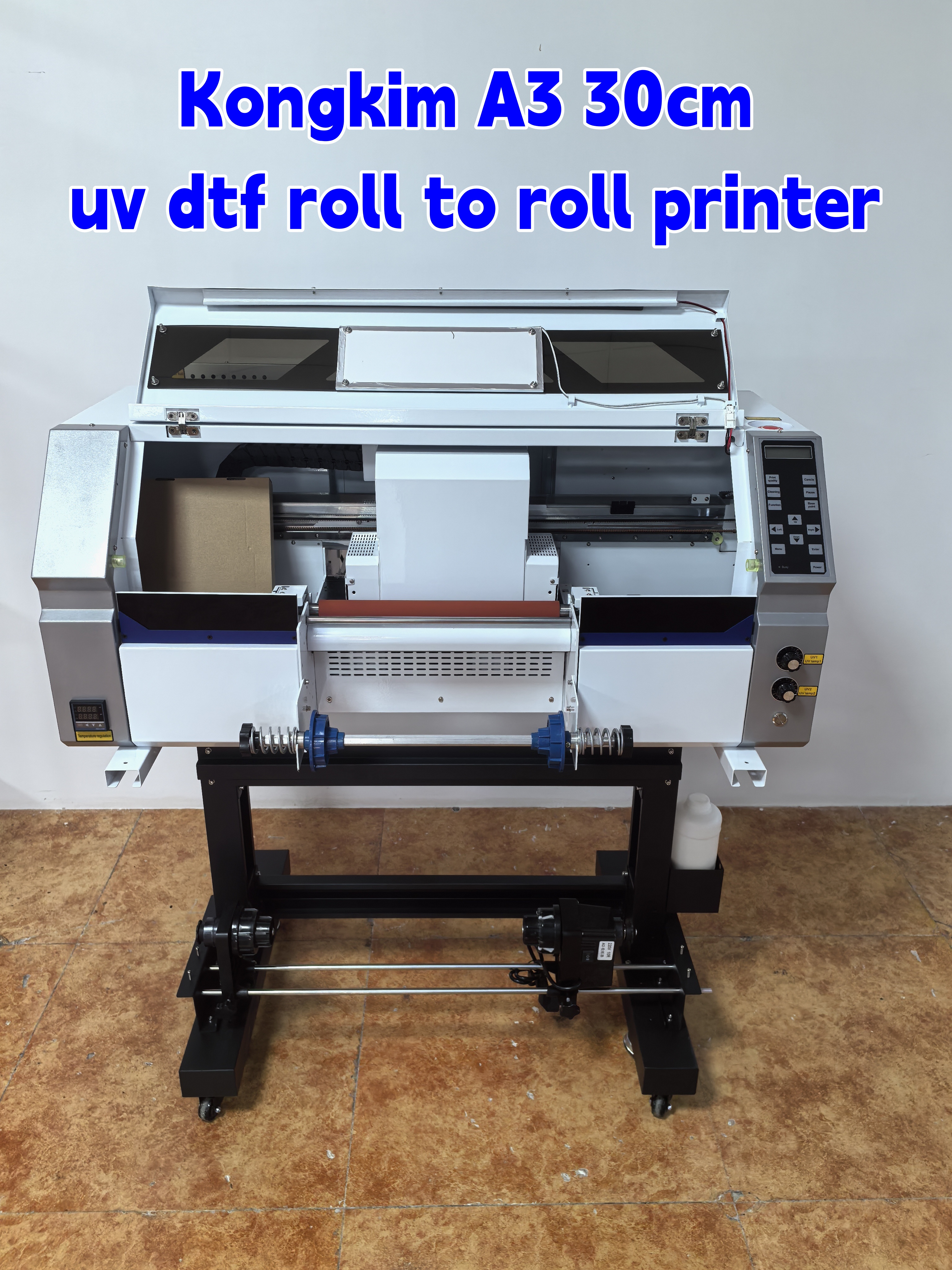

On the other hand, the 30cm 60cm roll-to-roll UV DTF printer directly prints on the UV DTF film and then transfers it to items. This method is ideal for mass production, offering improved efficiency. However, it is important to note that it cannot print directly on rigid and hard items.

Both printing methods result in UV DTF film with a 3D effect, producing realistic, clear, colorful, and three-dimensional patterns. The transfer effect is suitable for various products and offers high firmness, making it a desirable choice for many applications.

Ultimately, the decision between the 12inch 24inch UV DTF flatbed inkjet printers and the UV DTF roll-to-roll machine printer depends on the specific needs of the printing project. If versatility and the ability to print on a wide range of items is a priority, the flatbed printer may be the better option. However, for high-volume production and improved efficiency, the roll-to-roll printer may be the preferred choice.

In conclusion, both UV DTF printing methods offer unique benefits, and the choice between the two ultimately depends on the specific requirements of the printing project. Understanding the differences between the two methods is crucial in making the right decision for achieving the desired printing results.

Post time: Aug-28-2024