DTF Printing vs DTG Printing: Let’s Compare with Different Aspects

When it comes to garment printing, DTF and DTG are two popular choices. Consequently, some new users get confused about which option they should choose.

If you are one of them, read this DTF Printing vs. DTG Printing post till the end. We will do a comprehensive analysis of both printing techniques considering different aspects.

After going through this post, you can choose the best printing procedure based on your printing requirements. Let us first learn the basics of these two printing technologies.

DTG Printing Operation Process Overview

DTG or Direct-to-garment printing enables people to print straight on fabric (mainly cotton faric). This technology was introduced in the 1990s. However, people started using it commercially in 2015.

DTG printing ink straight onto the textile that goes into the fiber. DTG printing is carried out in the same manner (operation process ) as printing a a3 a4 paper on a desktop printer.

DTG printing operation process in the following steps:

First, you prepare the design on your computer with the help of software. Thereafter, a RIP (Raster Image Processor) software program translates the design image into a set of instructions a DTG printer can understand. The printer uses these instructions to print the image on the textile directly.

In DTG printing, the garment is pretreated with a unique solution before printing. It ensures bright colors while preventing ink absorption into the clothing.

After pretreatment, the garment gets dried using a heat press.

After that, that garment is placed onto the plate of the printer. Once the operator gives the command, the printer starts printing on garment by using its controlled print heads.

At last, the printed garment is heated once again with a heat press or heater to cure the ink, so that the printed inks won’t fade away after washing.

DTF Printing Operation Process Overview

DTF or Direct-to-Film is a revolutionary printing technology which was introduced in 2020. It helps people print a design onto a film and then transfer into different type garments. The printed cloth could be cotton, polyester, blended material, and more.

DTF printing operation process in the following steps:

Preparing a design

First, you prepare a design on a computer system with the help of software like Illustrator, Photoshop, etc.

Printing Design onto the PET Film (DTF film)

The built-in RIIN software of the DTF printer translates the design file onto PRN files. It helps the printer to read the file and print the design onto the (polyethylene terephthalate) PET film.

The printer prints the design with a white layer, helping it to be more noticeable on t-shirts.Printer will print any colors designs automatically on the pet film.

Transferring the print onto the garment

Before transferring the print, the pet film is powdered and heated (by the powder shaker machine, which is together with dtf printer) automatically. This process helps the design adhere to the garment. Next, the pet film is placed on the garment and then heat-pressed (150-160’C) for about 15 to 20 seconds. As soon as the cloth is cool, the PET film is peeled off gently.

DTF Printing vs DTG Printing: Comparison In Different Aspects

Startup Cost

For some people, especially new users, the startup cost might be the main determining factor. Compared to the DTF printer, the DTG printer is more costly. In addition, you will need a pre-treatment solution and a heat press.

To accommodate bulk orders, you will also need a pre-treatment machine and drawer heater or tunnel heater.

On the contrary, DTF printing involves the use of PET films, a powder shaking machine, a DTF printer, and a heat press. The cost of a DTF printer is lower than that of a DTG printer.

So in terms of startup cost, DTG printing is expensive. DTF printing win.

Cost of Ink

The ink used in direct-to-garment printing is comparatively expensive, we call them in DTG ink . The price for white ink is higher than others’ inks. And in DTG printing, white ink is used as a base to print on black textiles.and need to buy the pre-treatment liquid too.

DTF inks are cheaper. DTF printers utilize around half of the white ink as DTG printers do. DTF printing win.

Fabric Suitability

DTG printing is suitable for cotton and certain cotton-blend textiles, better in 100% cotton. The printing method uses pigment ink which is quite stable water-based ink. It is suitable for cotton textiles having low stretchability.

DTF printing allows you to print on variuous fabric , like silk, nylon, polyester, and more. You can even print specific parts of your garments made of different materials, such as collars, cuffs, etc.

Durability

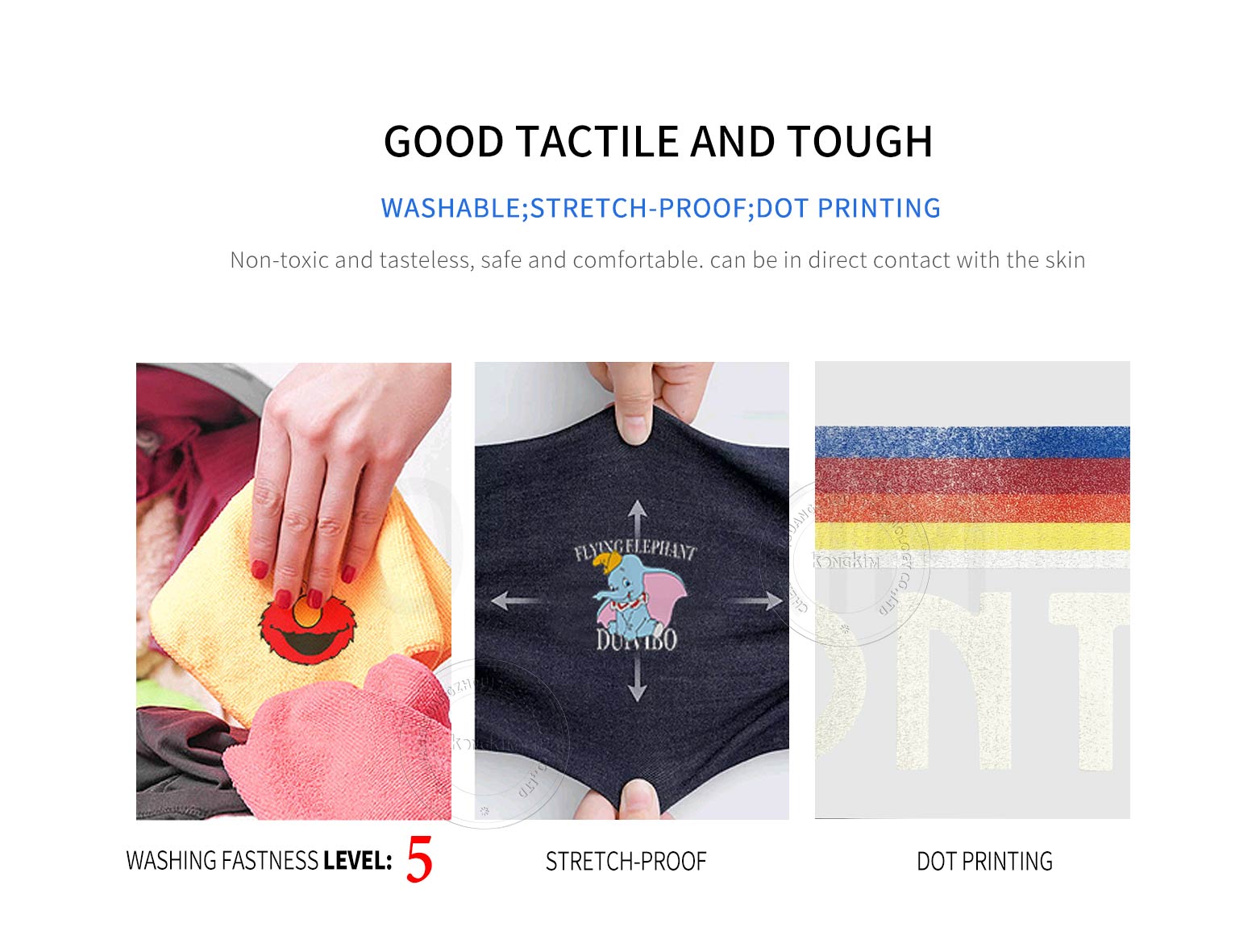

Washability and stretchability are two primary factors that decide the durability of the print.

DTG printing is direct printing on the garment. If DTG prints are properly pretreated, they can last up to 50 washes easily.

DTF prints, on the other hand, are good at stretchability. They do not tear apart and get stretch marks easily. After all, DTF prints are affixed to a cloth using a melting adhesive.

If you stretch DTF prints, they return to their shape again. Their washing performance is slightly better than DTG printing.

Both DTG and DTF printers are easy to maintain. Regular cleaning and maintenance ensure good print quality and performance. Operators are advised to clean the nozzles of the ink system frequently to prevent clogging. Also, keep the circulation system turned on when using the printer.

Our professional technicians team will guide you to maintain printer well.

Which Printing Techniques Should You Choose ?

Both printing methods are excellent in different ways. The choice depends on your business.

If you get small printing orders for cotton textiles with complex designs, DTG printing is ideal for you our KK-6090 DTG Printer

On the other hand, if you accommodate medium-to-large printing orders for multiple textile types, DTF printing is worth investing in.our KK-300 30cm DTF Printer , KK-700 & KK-600 60cm DTF Printer

Post time: Sep-20-2023